When factories around the world order a tray sealing machine, a MAP tray sealer, or a vacuum skin packaging machine from DJPACK (Wenzhou Dajiang Vacuum Packaging Machinery Co., Ltd.), one question frequently comes up:

“Why do I need to send my trays and film to your factory?”

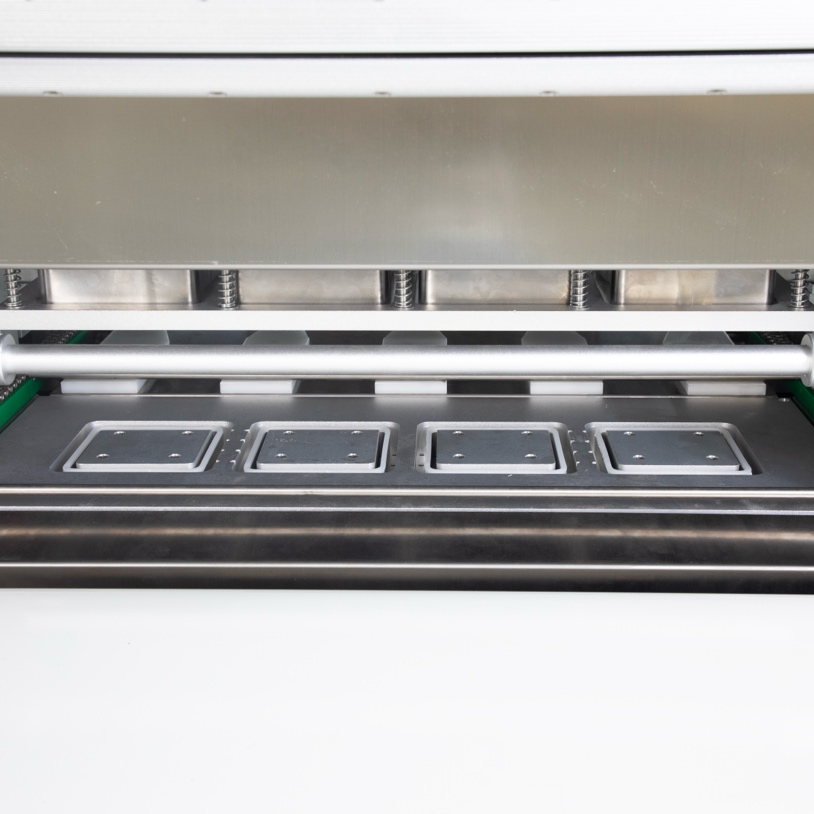

At first glance, it may seem like an extra step. But for packaging equipment, this step is essential. In fact, it is the most reliable way to ensure a new machine performs flawlessly the moment it arrives at a customer’s facility.

This article explains—using simple language and real engineering logic—why sample trays and films matter, how they influence mold accuracy, and why global factories benefit from this process.

1. Every Tray Looks Simple Until You Try to Seal It

To many buyers, a plastic tray is just a plastic tray.

But to a manufacturer of tray sealing machines, every tray is a unique object with its own geometry, its own material behavior, and its own sealing requirements.

1.1. The Dimensions Problem: Everyone Measures Differently

Customers from different countries measure lengths in different ways:

- Some measure internal dimensions (usable space inside the box).

- Others measure the outer rim (which directly affects mold design).

- Some measure only the bottom footprint, not the top opening.

- Others ignore the height of the flange.

This leads to misunderstanding because a custom mold needs exact rim-to-rim data, not approximate numbers. Even a 1- 2mm deviation can affect sealing performance.

When DJPACK receives physical trays:

- Engineers can take precise measurements

- The mold is designed with the correct rim profile

- No risk of “tray doesn’t fit the mold” or “film won’t seal” issues

2. Around the World, Trays Come in Endless Shapes

Even if two trays share the same volume or size label, their physical structure can be totally different. This is the part most buyers don’t realize until they purchase a sealing machine.

2.1. Tray Rim Width Varies by Region

Some countries produce trays with narrow sealing rims; others prefer wide rims for strength.

A mold must match these rims exactly—otherwise the sealing bar cannot deliver consistent pressure.

2.2. Trays Can Be Vertical, Angled, or Curved

Tray walls may be:

- perfectly vertical

- slightly tapered

- deeply angled

- subtly curved

These small differences influence how the tray sits inside a mold and how the sealing pressure distributes across its surface.

2.3. The Flange Angle Is Not Always Straight

In many trays, the flange is not flat—it is slightly curved, bent, or reinforced for stacking. This angle directly affects sealing accuracy. If the mold does not match the angle, air leaks can appear even when temperature and pressure are correct.

2.4. Sample Trays Allow Perfect Mold Adaptation

DJPACK’s engineers evaluate:

- rim flatness

- thickness

- flange behavior under pressure

- wall stability

- tray elasticity under heat

This enables them to design molds that are not only accurate but also stable under repeated sealing cycles, giving customers consistent results and longer machine life.

3. Why DJPACK Requires at Least 50 Trays for Testing

Many customers ask: “Why do you need so many trays? Isn’t a few enough?”

Actually, no.

3.1. Some Trays Cannot Be Reused After Testing

When a tray is heat-sealed and the film is peeled off for inspection:

- A PE-coated tray may tear

- The flange may deform

- Adhesive layers may stretch

- The tray may warp slightly under heat

Once this happens, the tray cannot be used for another test.

3.2. Multiple Tests Are Required for Calibration

To optimize factory settings, engineers must run dozens of tests to determine:

- best sealing temperature

- ideal sealing time

- correct pressure value

- alignment accuracy

- mold opening/closing smoothness

- film tension behavior

Each test consumes trays.

3.3. Deformation Happens After Repeated Heat Exposure

If only a few trays are supplied, the same trays end up being tested repeatedly. Heat, pressure, and mechanical movement can gradually deform them. A deformed tray can mislead the engineer into thinking:

- the mold is incorrect

- the machine has alignment issues

- the sealing bar has uneven pressure

Only fresh and undeformed trays allow accurate judgment.

3.4. Adequate Samples Protect Both Buyer and Manufacturer

Enough trays ensure:

- No risk of inaccurate mold sizing

- Reliable factory test results

- Smooth machine acceptance

- Fewer problems during installation

- Guaranteed sealing performance on arrival

It truly benefits both manufacturer and clients.

4. Why Tray Materials Matter More Than Most Buyers Expect

Trays used for sealed packaging are made from a variety of materials:

- PP (Polypropylene)

- PET / APET

- CPET

- Multilayer PP-PE

- Eco-degradable plastics

- Aluminum trays

- PE-coated paper trays

Each material has completely different behavior under heat.

4.1. Different Melting Temperatures

For example:

- PP trays require higher sealing temperatures

- PET trays soften quickly and need lower temperatures

- CPET trays tolerate high heat for oven use

- PE coatings have specific melting activation points

4.2. Heat Conductivity Affects Sealing Time

Some materials absorb heat slowly.

Some absorb heat too quickly.

Some soften unevenly.

DJPACK adjusts sealing time and pressure based on these behaviors.

4.3. Film Type Must Match Tray Material

A mismatch can cause:

- weak seals

- melted rims

- film breaking under heat

- sealing wrinkles

This is why sending trays-and their corresponding films-helps ensure the correct engineering decisions.

5. Why Films Are Just as Important as Trays

Even if the correct tray is used, a film mismatch can ruin sealing.

5.1. Film Formulations Differ by Application

Films vary by:

- thickness

- layer structure

- heat-activation layer

- sealing strength

- shrink behavior

- Stretch Strength

- oxygen transmission rate

MAP tray sealer and vacuum skin packaging machine applications especially require precisely matched films.

5.2. DJPACK Does Not Force Customers to Send Film

But sending film always results in:

- better settings

- more accurate testing

- smoother first-time use

If customers cannot send film, they must at least specify the material. This allows DJPACK to use equivalent films during testing.

5.3. Film–Tray Compatibility Must Be Verified

Film must be suitable for the tray material.

Film must seal cleanly without bubbles or leaks.

Film must peel correctly (if easy peelable type).

Testing ensures all three conditions are met.

6. What If Customers Do Not Have Trays or Film Yet?

DJPACK supports new factories and startups that do not yet have packaging materials.

6.1. Consumables Can Be Purchased Through DJPACK

The company can help source:

- Variable Scale of Trays

- VSP film

- MAP lidding film

- Variable Scale of Trays

This effectively reduces the purchasing pressure for startups—we help you find reliable and stable consumables suppliers

6.2. Materials Used for Testing Are Shipped With the Machine

This ensures that when the customer receives the tray sealing machine, they can immediately:

- test

- adjust

- compare

- train operators

Reduce setup and consumables arrival time to get into production faster.

6.3. Long-term Supplier Recommendations Available

For larger production needs, DJPACK can recommend stable suppliers, making it easier for customers to buy trays and films later.

7. Final Thoughts: Samples Today Ensure Perfect Sealing Tomorrow

In the world of food packaging, precision is everything. A tray that looks simply is actually a complex engineered product. And when matched with the right mold and film, it becomes a powerful combination for freshness, safety, and shelf life.

Sending trays and film is not an inconvenience.

It is the foundation of:

- accurate mold design

- stable machine operation

- perfect sealing quality

- fewer problems after installation

- faster startup

- longer equipment life

DJPACK’s commitment is simple:

Every machine should work perfectly the moment it reaches the customer.

And the best way to guarantee that is to start with the real trays and real films the customer will use.

Post time: Dec-15-2025

Phone:0086-15355957068

Phone:0086-15355957068 E-mail: sales02@dajiangmachine.com

E-mail: sales02@dajiangmachine.com