Modern MAP tray sealers can either directly inject a preservative gas mixture (“air-flush”) into the tray or first evacuate air and then fill it. Our Wenzhou Dajiang (DJPACK) tray sealers clearly mark this choice: models ending in G are gas-flush machines, while those ending in V are vacuum-flush machines. MAP (Modified Atmosphere Packaging) machines fill trays with a controlled gas mix (typically N₂, CO₂, O₂) to protect food. By replacing ordinary air with an inert gas environment, MAP greatly extends shelf life and preserves color, flavor and texture.

Tray sealers can handle various containers (trays, cups, bowls) and load fresh foods (meat, produce, salads, ready meals, etc.) before sealing the film. For example, the DJL-370G (gas-flush) and DJL-370V (vacuum-flush) are identical tray sealers except for their flush method. In the sections below, we explain how each flush mode works, its use cases, and the benefits of each.

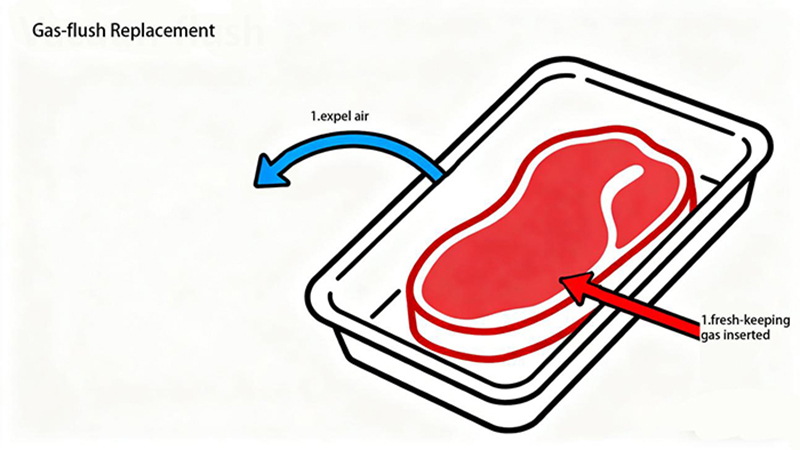

Gas Flush (Air-Flush) Packaging

In gas-flush packaging, the machine directly injects a protective gas mixture into the tray to displace the air before sealing. In practice, an inert gas is introduced into the package, pushing nearly all the air out. When the MAP gas is injected at a much higher pressure—about five to six times stronger than the air inside the tray—it squeezes the air out of the container and replaces it with the protective gas. The tray is then sealed with the new atmosphere inside. No vacuum stage is used – the tray remains at or near ambient pressure throughout sealing.

This method is faster than vacuum-flush replacement. For example, our floor type model DJL-370G (gas-flush) sealer can run about 5–6 cycles/min in theory, significantly faster than the 3–4 cycles/min for the vacuum model. Gas-flush machines also use a simpler mechanism (no heavy-duty vacuum chamber or large pump), so they consume less power and are lighter. (In fact, DJL-370G is only 170 kg vs 265 kg for DJL-370V, and 2.4 kW vs 3.5 kW power.) This translates into lower equipment and running cost.

Common advantages of gas-flush MAP include:

1.Ideal for products that do not require extremely low residual oxygen:

Particularly red meats such as beef, lamb, and organ products, which actually need a certain level of oxygen inside the tray to maintain their natural bright color and fresh appearance.

2.Significantly higher working efficiency:

The system eliminates the long vacuum-pumping stage, resulting in shorter cycle times and higher output compared with vacuum-replacement models.

3.Lower machine cost:

Since no vacuum chamber or vacuum pump is required, the overall construction is simpler and more economical, reducing both manufacturing and maintenance costs.

4.Lower power consumption:

Gas-flush machines typically require less electrical power and can often operate on a standard single-phase power supply.

5.High gas-exchange efficiency:

The flushing process can achieve a gas replacement rate of over 99%, ensuring excellent MAP performance for a wide range of products.

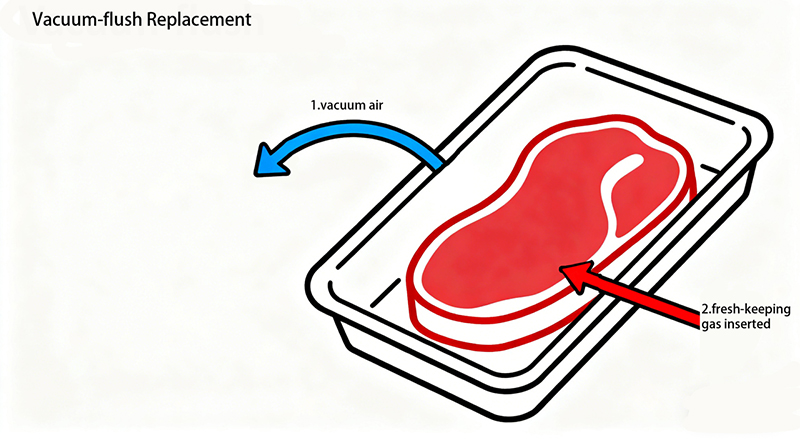

Vacuum Flush (Vacuum-Replacement) Packaging

In vacuum-flush packaging, the machine first creates a vacuum and then backfills with gas. Specifically, a chamber vacuum pump removes almost all air from the sealed tray. Once a strong vacuum (near-zero pressure) is reached, the system injects the protective gas into the chamber and tray. Finally, the tray is sealed once chamber pressure is normalized.

This two-step process (vacuum then gas) achieves a very low residual O₂ – often ≤0.5%. During the vacuum step, the machine maintains equal pressure inside the tray and within the chamber, ensuring the product is not deformed by pressure differences. After the vacuum phase, the system introduces the MAP gas mixture into the tray and proceeds with heat sealing, completing the entire packaging cycle.

Because a heavy vacuum pump and sealed chamber are needed, vacuum-MAP machines are larger, heavier and more complex. Larger vacuum chambers require vacuum pumps with higher pumping speeds. For example, in our floor-type models, the pump capacity increases with the machine size. The largest standard model, the DJL-440V, is equipped with a 100 m³/h vacuum pump. Custom configurations are also available upon request.

Cost-wise, vacuum models require expensive vacuum valves and pumps, raising machine price. However, vacuum-MAP delivers the highest gas exchange: tests show up to 99.5% of air can be removed.

Common advantages of gas-flush MAP include:

1.Extremely low residual oxygen levels:

Vacuum-replacement systems are ideal for products that require very strict control over residual oxygen. By removing the air first and then backfilling with the MAP gas mixture, the system can achieve a much lower O₂ level than gas-flush systems. This is especially beneficial for products that are highly sensitive to oxidation or microbial growth.

2.Lower gas consumption and overall operating cost:

Although gas-flush (G-type) machines have lower equipment cost, vacuum-replacement systems can significantly reduce the running cost by consuming much less MAP gas.

With gas-flush systems, protective gas must be injected in large quantities to physically push the existing air out of the tray. To ensure complete displacement, additional gas is always required, which inevitably leads to some degree of waste.

In contrast, vacuum-replacement systems only need enough gas to equalize the pressure inside the tray after the vacuum phase. Since most of the air has already been removed, very little MAP gas is needed to refill the tray, resulting in notably lower consumption.

Therefore, customers often evaluate machine cost vs gas cost when choosing between G-type and V-type models, selecting the option that provides the most cost-effective long-term operation.

3.More effective for applications requiring very precise gas ratios

For products that demand extremely low residual oxygen or large-scale machine scale, vacuum replacement can be more efficient.

Because gas-flush systems rely on directional gas flow to push air out, certain corners or irregular areas of the tray can be harder to purge completely. This makes it more challenging to reach extremely strict gas ratios or ultra-low oxygen levels.

Vacuum-replacement systems do not have this limitation. Since the air is removed entirely before refilling, the MAP gas mixture fills the tray uniformly, ensuring a more accurate and consistent atmosphere. In many cases, vacuum replacement achieves the required gas ratio faster and more thoroughly than gas-flush methods.

Gas Flush vs Vacuum Flush: Comparison

| Replacement Method | Gas Flush (G model) | Vacuum Flush (V model) |

| Working principle | Inject inert gas (N₂/CO₂) directly into tray, displacing air; no vacuum drawn. | Evacuate almost all air first (vacuum pump), then backfill with gas mix. |

| Machine complexity | Simpler – no large vacuum chamber or pump needed. | More complex – requires sealed vacuum chamber and vacuum pump. |

| Cycle speed/efficiency | High throughput due to skipping vacuum stage. | Slower cycle because of vacuum draw-down and pressure equalization. |

| Residual oxygen/gas efficiency | Very high gas-flow means > 99% exchange in many cases. | Even higher purity: can reduce residual O₂ to very low levels, with less gas wasted. |

| Operating cost drivers | Uses more protective gas (because gas must flush out the original air). | Lower gas consumption: after vacuum, only refill is needed, so gas costs are more economical. |

| Ideal use cases | Products that don’t need ultra-low O₂: red meat (where some O₂ is good for color), fresh produce. | Applications with very strict O₂ control: oxygen-sensitive foods, long shelf life needed, or where gas cost is a concern, like cooked food. |

| Cost considerations | Lower machine cost (no vacuum system) | Higher equipment cost (vacuum pump, chamber), but lower long-term gas usage |

Conclusion

Choosing between Gas Flush (“G” type) and Vacuum Flush (“V” type) for your tray-type MAP machine depends on your product characteristics, production priorities, and cost considerations.

- If your priority is high-speed production and you are packaging products that do not require ultra-low residual oxygen — such as red meat, deli items, or products where appearance and color are critical — the Gas Flush (G) model is often the best choice. It gives you fast cycle times, lower equipment cost for your products.

- On the other hand, if your product demands very low residual oxygen, or you want to minimize the consumption of protective gas, the Vacuum Flush (V) model may offer superior cost efficiency in the long run. Despite the higher upfront cost (vacuum pump, sealed chamber), its low gas usage and high displacement efficiency can make it more economical for certain applications.

At Wenzhou Dajiang / DJPACK Machinery, our tray sealers are designed to support both modes — simply select the suffix “G” or “V” when you choose your model (e.g., DJL-440G or DJL-440V). This flexibility allows you to balance machine cost, production speed, gas consumption, and product quality to best suit your business needs.

Post time: Nov-24-2025

Phone:0086-15355957068

Phone:0086-15355957068 E-mail: sales02@dajiangmachine.com

E-mail: sales02@dajiangmachine.com