Modified Atmosphere Packaging (MAP) is a preservation method in which the natural air inside a package is replaced with a controlled mixture of gases–typically oxygen, carbon dioxide, and nitrogen–to keep food fresh for longer. By slowing down the chemical and biological processes that lead to spoilage, MAP can significantly extend shelf life. In many cases, it increases freshness by two to five times compared with standard air packaging. This extended durability not only reduces food waste but also supports long-distance distribution and often allows processors to reduce preservative use.

The Functional Roles of Each Gas in MAP

Each gas in a MAP mixture contributes a specific function:

• Oxygen (O₂)

Oxygen supports color and freshness in several food categories. Red meat, for example, maintains its attractive bright-red oxymyoglobin pigment when exposed to high oxygen levels, typically around 70–80%. For fruits and vegetables, small amounts of oxygen (around 2–5%) are used to support natural respiration. However, excess oxygen accelerates fat oxidation and shortens shelf life, so its presence must be carefully controlled.

• Carbon Dioxide (CO₂)

Carbon dioxide functions primarily as an antimicrobial gas. When CO₂ dissolves in the moisture on the product surface, it forms a weak carbonic acid that helps inhibit the growth of spoilage bacteria and mold. MAP mixtures commonly rely on 20–30% CO₂. Higher concentrations can further extend shelf life, but because CO₂ is absorbed into the food, it may cause package collapse unless balanced with nitrogen.

• Nitrogen (N₂)

Nitrogen is inert and does not react with food. Its main purpose is to displace oxygen and to maintain package structure, particularly when CO₂ is absorbed into the product. It typically makes up the remaining percentage of the gas mix (often 50–80%) once O₂ and CO₂ levels are set.

In summary:

• O₂ preserves color and respiration,

• CO₂ suppresses microbial growth,

• N₂ provides volume and stability.

Different foods require different balances of these gases, as described below.

Raw Meats and Poultry

Raw Red Meat

Fresh red meats, such as beef, lamb, and pork–commonly rely on high-oxygen MAP. Retail and wholesale packs frequently use a mixture of 65% O₂ and 35% CO₂. The strong oxygen presence keeps the meat bright red, while CO₂ helps slow aerobic bacterial growth. In some cases, processors may reduce oxygen by about 5% to gain additional shelf life. Any residual headspace is commonly nitrogen or left as near–vacuum.

Raw Poultry

Poultry and game birds (chicken, turkey, pheasant) typically require no oxygen in the package. A standard mixture is 0% O₂, around 30% CO₂, and 70% N₂. Because poultry meat is naturally pale, oxygen does not contribute to appearance. CO₂ provides microbial control, while nitrogen ensures the pack maintains its shape. Some bulk processors use 100% CO₂ for maximum preservation.

Key takeaway:

• Red meats benefit from high-oxygen mixes for color retention.

• Poultry is best preserved with a CO₂/N₂ mixture without oxygen.

Testing is always recommended for final confirmation.

Fresh Fish and Seafood

The ideal MAP composition depends largely on whether the fish is lean or high in fat.

Low-Fat Raw Fish & Shellfish

White fish species (cod, haddock, bass) and most shellfish (shrimp, mussels, scallops) frequently use 30% O₂, 40% CO₂, and 30% N₂. Oxygen helps maintain natural color, CO₂ slows microbial activity, and N₂ fills the remaining headspace. For large-volume or frozen shipments, processors may switch to 70% CO₂ / 30% N₂ for extended storage.

High–Fat Raw Fish

Fatty fish such as salmon, tuna, mackerel, and sardines are packed without oxygen because their oils oxidize very quickly. A common MAP blend is 40% CO₂ and 60% N₂. Some producers increase CO₂ to 50–70% for added protection. Retail salmon often uses 40/60 CO₂/N₂, while tuna may use 30–40% CO₂ with nitrogen making up the balance. Bulk packs sometimes employ 70% CO₂ / 30% N₂.

Summary:

• Lean seafood often uses ~30% O₂,

• Oily fish rely strictly on CO₂/N₂ mixtures with 0% oxygen.

Regardless of the mix, MAP always works best together with proper cold-chain control.

Cooked and Cured Meats, Fish, and Poultry

Once meat or fish has been cooked or cured, color becomes stable and the objective shifts to preventing mold and microbial spoilage.

Cooked or Cured Meats

Items like ham, sausages, and salami typically use 30% CO₂ / 70% N₂. For bulk or export applications, processors may raise CO₂ to 50% CO₂ / 50% N₂. Oxygen is kept at zero.

Smoked or Cured Fish

Smoked salmon and similar products often use 30% CO₂ / 70% N₂ in retail trays. For extended storage, a 70/30 CO₂/N₂ blend may be applied.

Cooked/Cured Poultry

Processed sliced turkey or chicken products follow the same approach:

• Retail: 30% CO₂ / 70% N₂

• Bulk: 70% CO₂ / 30% N₂

Across this category, oxygen is consistently 0%.

Ready Meals and Combination Foods

Prepared meals such as pasta dishes, stews, or pizzas are generally sealed with oxygen-free MAP. The most common mixture is 30% CO₂ / 70% N₂. For export or extended storage, processors may choose 50% CO₂ / 50% N₂.

These mixtures slow microbial growth across a blend of ingredients. Because ready meals vary widely, initial ratios are used as reference points and must be validated through testing.

Pasta and Bakery Products

Fresh Pasta

Fresh, uncooked pasta (such as ravioli, noodles, or tortellini) is typically packaged under a 50% CO₂ / 50% N₂ mixture. Oxygen is avoided entirely.

Bakery Products

Bread, buns, tortillas, and cakes often rely on 50% CO₂ / 50% N₂ in retail. For bulk distribution, CO₂ may increase to 70% (70% CO₂ / 30% N₂). Nitrogen prevents the packaging from collapsing, while CO₂ inhibits mold growth. Oxygen remains near zero to prevent staling or rancidity.

Cheese (Hard, Soft, Grated)

Hard or Aged Cheeses

Products such as Parmesan or aged Cheddar are often packaged with 100% CO₂ or vacuum-sealed. This approach is highly effective at suppressing mold.

Soft and Shredded Cheeses

Cream cheese, Brie, cottage cheese, and shredded mozzarella frequently use 30% CO₂ / 70% N₂. The nitrogen stabilizes the packaging, while CO₂ minimizes microbial growth.

Summary:

• Hard cheeses → 100% CO₂

• Soft & shredded cheese → 30% CO₂ / 70% N₂

Vegetables, Salads, and Fruits

Fresh Whole Produce

Whole fruits and vegetables typically require a delicate balance that supports respiration without promoting spoilage. A standard MAP blend is 5% O₂, 5% CO₂, and 90% N₂. This low-oxygen environment slows respiration and browning. This mix is widely used for salads, leafy greens, berries, and cut fruit.

Cooked or Cut Vegetables

Prepared vegetables behave similarly to ready meals. They commonly use 30% CO₂ / 70% N₂ with no oxygen. This approach works well for items like potato salads or mixed vegetable dishes.

Key point:

Fresh produce needs a small amount of oxygen (~5%), while cooked vegetables rely on higher CO₂ (~30%).

Dried Foods

Dried goods such as coffee, nuts, snacks, teas, spices, and flour are typically sealed with 100% N₂. Nitrogen prevents oxidation and extends shelf life.

Choosing MAP Equipment (DJPACK)

Accurate gas mixing is essential for effective MAP. DJPACK (Wenzhou Dajiang) manufactures a range of MAP tray sealers designed for precise gas flushing. The tabletop DJT-400G and the floor-standing DJL-400V are capable of delivering consistent O₂/CO₂/N₂ ratios according to the needs of different foods–from fresh meats to ready meals or salads. We also have several models for your needs. If you are interested in our machines, please click “Products→Modified Atmosphere Packaging Machines” button to learn more.

With more than 30 years of experience in packaging machinery, DJPACK equipment is widely used by processors in Europe, Australia, Asia, and other developed markets. No matter what gas ratio the customer requires, our equipment can achieve it, and the gas-mixing accuracy consistently remains above 99%. Our Vacuum Replacement MAP machines always attach about 99.5%.

Safety, Testing, and Quality Assurance

MAP ratios are guidelines–not fixed rules. Actual performance depends on product formulation, packaging materials, temperature, and storage conditions. For this reason, every processor should perform real–world shelf–life trials to verify that the chosen MAP mixture achieves the intended results.

Quality assurance measures such as leak detection and headspace gas analysis are equally important. Even a small leak can compromise the atmosphere inside the package. MAP should always be used together with proper refrigeration, hygiene, and handling practices.

Disclaimer:

The gas ratios in this guide are suggested starting points. Always validate mixtures through product testing.

Conclusion

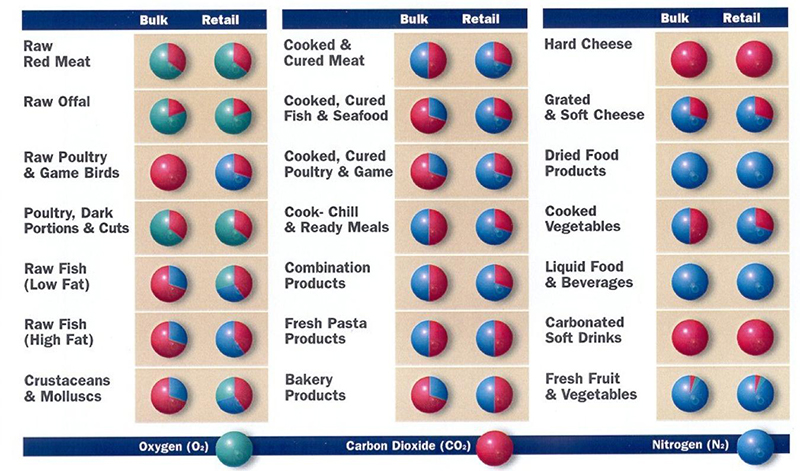

Modified Atmosphere Packaging enables food manufacturers to slow spoilage by tailoring the environment inside the package. Oxygen helps retain color, carbon dioxide suppresses microbial growth, and nitrogen stabilizes the pack. By applying the principles shown in the gas-mix chart, processors can choose suitable starting mixtures for meats, seafood, cheese, vegetables, bakery items, ready meals, and more.

MAP is most effective when paired with accurate machinery and solid quality control. When properly implemented, it ensures products remain fresher, safer, and market-ready–supporting longer supply chains while reducing waste.

The recommendations in this article summarize common industry practices and scientific guidelines. Final MAP settings should always be based on each customer’s product tests and storage requirements.

Post time: Dec-05-2025

Phone:0086-15355957068

Phone:0086-15355957068 E-mail: sales02@dajiangmachine.com

E-mail: sales02@dajiangmachine.com