DJL-320G Food Fresh Keeping MAP Tray Sealer

Description

MAP tray sealer can match different gas mixers. According to the difference of foods, people can adjust the gas ratio to minimize bacterial growth and realize the fresh-keeping effect. It is widely applicable to the package of raw and cooked meat, seafood, fast food, dairy product, bean product, fruit and vegetable, rice, and flour food.

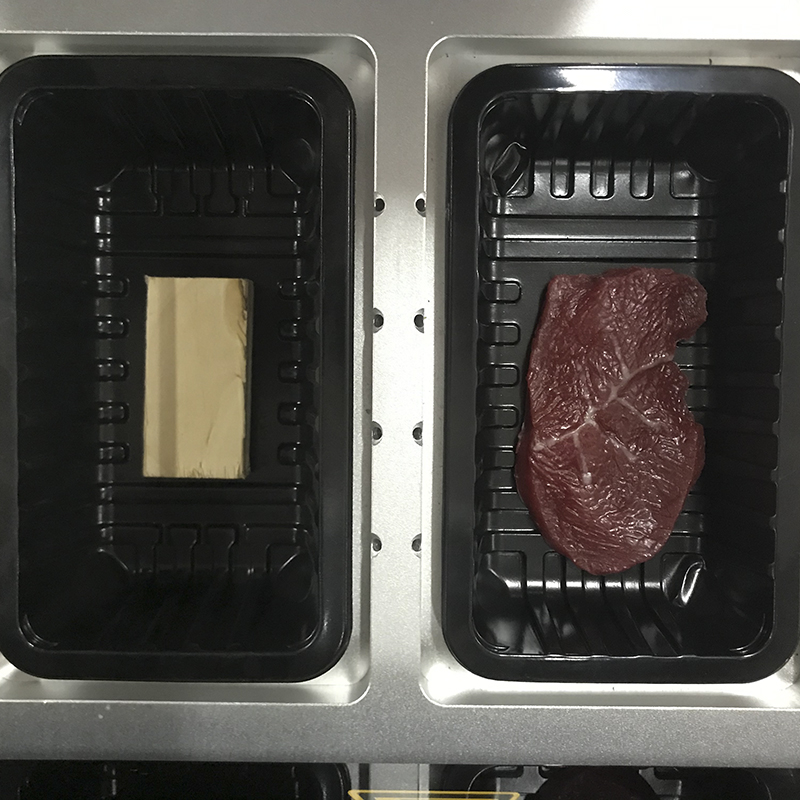

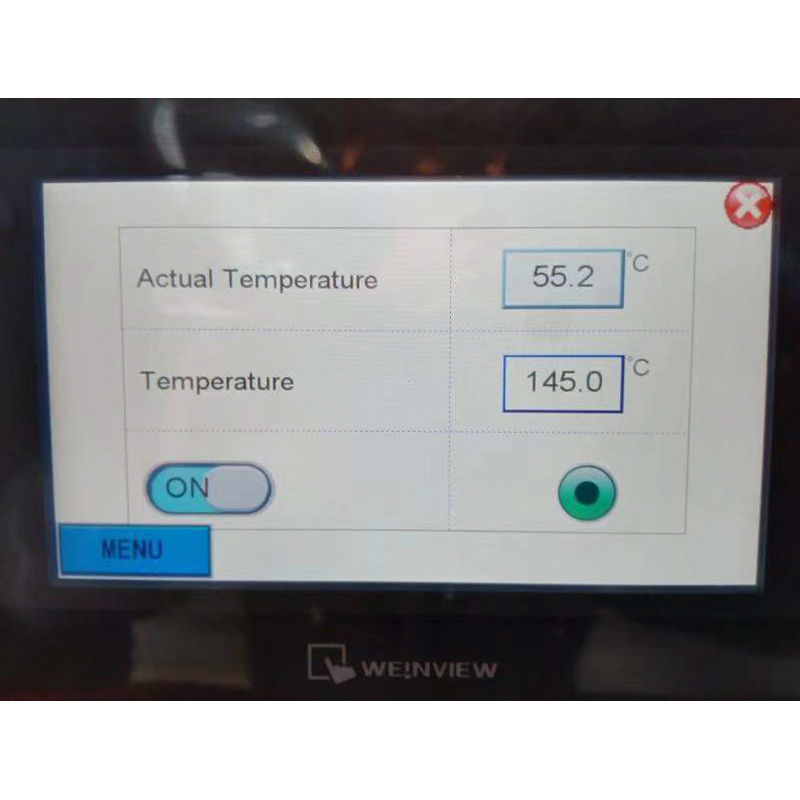

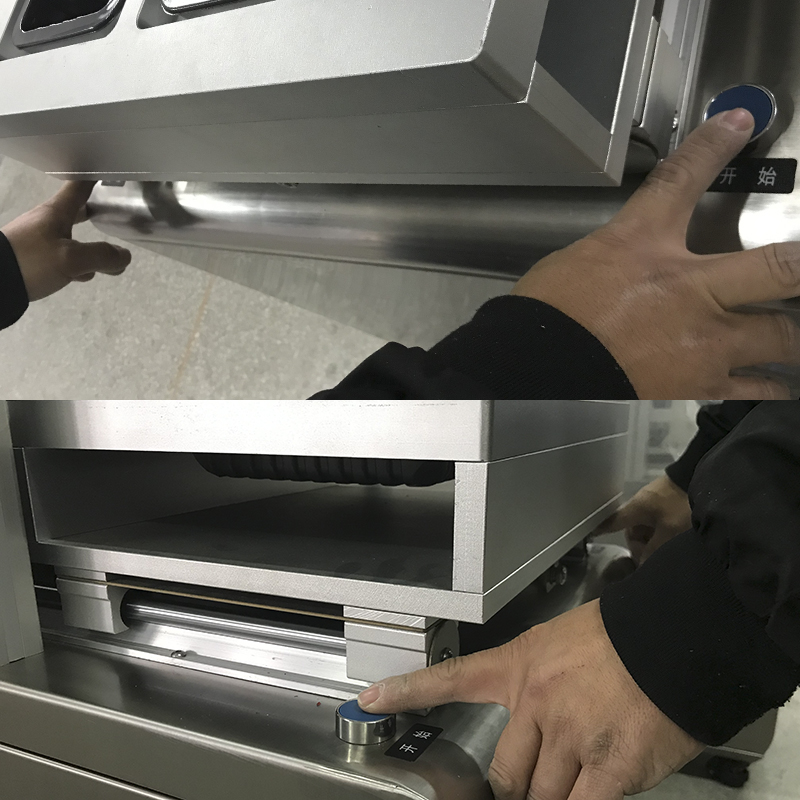

Work Flow

Step1: Insert the gas conduit and turn on the main switch

Step2: Pull the film to position

Step3: Put the goods into the tray.

Step4: Set the processing parameter and the packaging temperature.

Step5: Press the “on” button, and press the “start” button together.

Step6: Take the tray out

Advantages

● Minimize bacterial growth

● Fresh Kept

● Quality extended

● Color and shape ensured

● Taste retained

Tech Specs

Technical Parameter of the MAP Tray Sealer DJL-320G

| Max. Tray Dimension | 390 mm×260 mm×60 mm (×1)

260 mm×180 mm×60 mm (×2) |

| Max. Width of Film | 320 mm |

| Max. Diameter of Film | 240 mm |

| Packing Speed | 5-6 cycle/min |

| Air Exchanging Rate | ≥99 % |

| Electrical Requirement | 220V/50HZ 110V/60HZ 240V/50HZ |

| Consume Power | 1.5 KW |

| N.W | 125 kg |

| G.W | 155 kg |

| Machine Dimension | 1020 mm×920 mm×1400 mm |

| Shipping Dimension | 1220 mm×1120 mm×1600 mm |

Max. Mould(Die Plate) Format(mm)

Model

Full Range of Vision MAP Tray Sealer

| Model | Max. Tray Size |

| DJL-315G (Airflow Replacement) |

310 mm×220 mm×60 mm (×1) 220 mm×140 mm×60 mm (×2) |

| DJL-315V (Vacuum Replacement) | |

| DJL-320G (Airflow Replacement) |

390 mm×260 mm×60 mm (×1) 260 mm×180 mm×60 mm (×2) |

| DJL-320V (Vacuum Replacement) | |

| DJL-370G (Airflow Replacement) |

310 mm×200 mm×60 mm (×2) 200 mm×140 mm×60 mm (×4) |

| DJL-370V (Vacuum Replacement) | |

| DJL-400G (Airflow Replacement) |

230 mm×330 mm×60 mm (×2) 230 mm×150 mm×60 mm (×4) |

| DJL-400V (Vacuum Replacement) | |

| DJL-440G (Airflow Replacement) |

380 mm×260 mm×60 mm (×2) 260 mm×175 mm×60 mm (×4) |

| DJL-440V (Vacuum Replacement) |

Phone:0086-15355957068

Phone:0086-15355957068 E-mail: sales02@dajiangmachine.com

E-mail: sales02@dajiangmachine.com