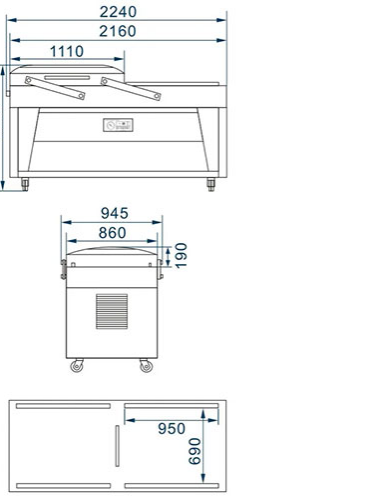

DZ-950 2S Double Chamber Vacuum Packaging Machine

Technology specifications

|

Model |

DZ-950-2S |

|

Machine Dimensions(mm) |

2240 × 945 × 1040 |

|

Chamber Dimensions(mm) |

1110 × 840 × 260 |

|

Sealer Dimensions(mm) |

950 × 8 × 2 |

|

Vacuum Pump(m3/h) |

200/300 |

|

Power Consumption(kw) |

5.5 |

|

Electrical Requirement(v/hz) |

220V/380/50 |

|

Production Cycle(times/min) |

1-2 |

|

Net Weight(kg) |

551 |

|

Gross Weight(kg) |

662 |

Technical characters

-

Control System: The PC control panel provides several control modes for user selection.

- Material of Main Structure: 304 stainless steel.

- Hinges on Lid: The special labor-saving hinges on the lid markedly reduce the labor intensity of operators in dally work, so that they handle it with ease.

- "V" Lid Gasket: The "V" shaped vacuum chamber lid gasket made of high-density material guarantees the sealing performance of the machine in routine work. The compression and wearing resistance of the material extends the service life of the lid gasket and reduces its changing frequency.

- Heavy Duty Casters (With Barke): The heavy-duty casters (with brake) on the machine features superior load-bearing performance, so that the user may move the machine with ease.

- Electrical requirements and plug could be custom according to customer requirements.

- Gas Flushing is Optional.

Phone:0086-15355957068

Phone:0086-15355957068 E-mail: sales02@dajiangmachine.com

E-mail: sales02@dajiangmachine.com